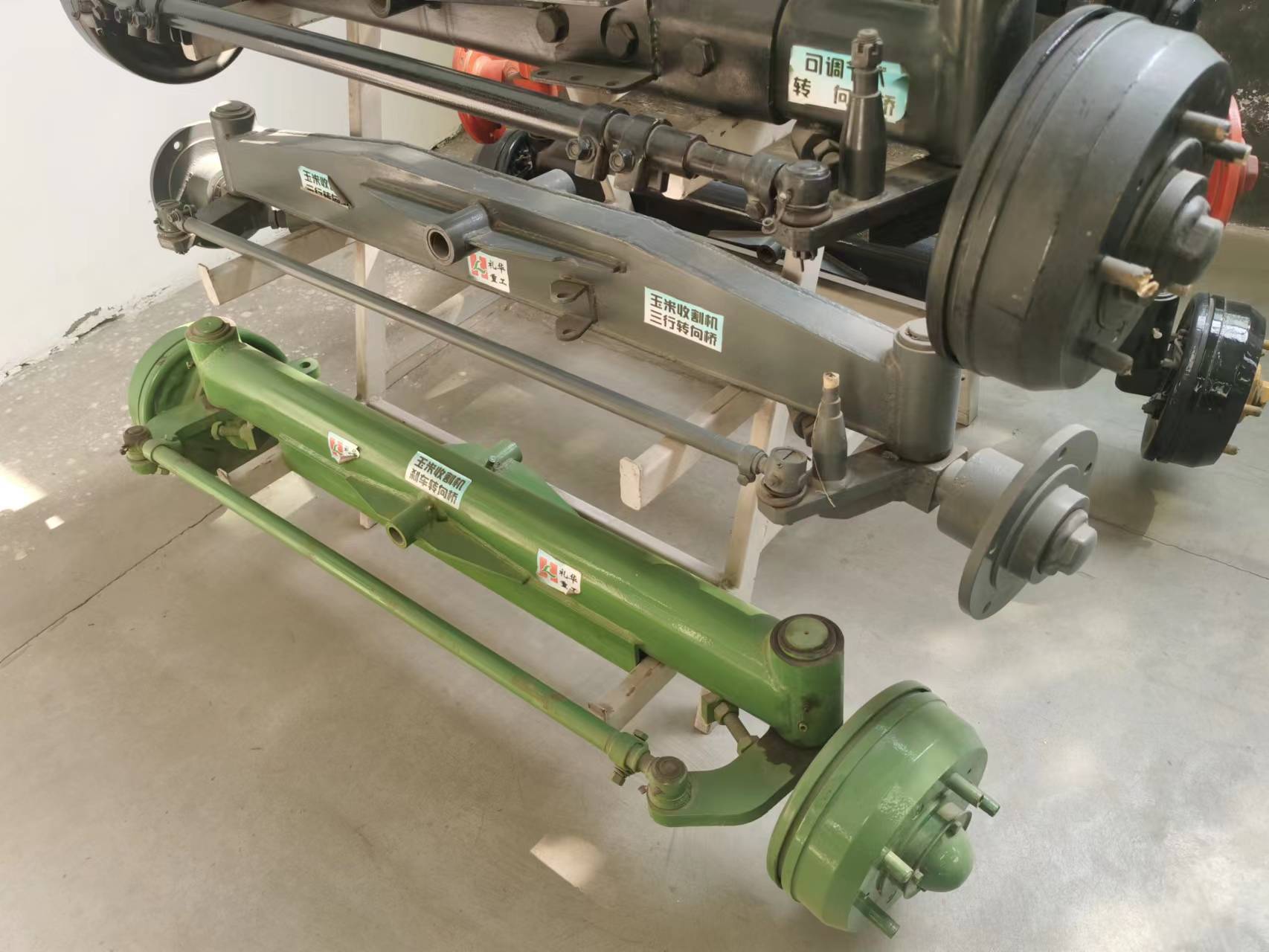

axle

-

China Factory Good Qualtiy Cheap Price Stub Axles For Corn Harvester

Now, there are more than 10 days before the corn ripening season. However, in a small village in Bozhou City, Anhui Province, a corn harvester is busy in the field. The most striking thing about this harvester is its size. There are few such large corn harvesters in rural areas.

Driving the harvester is a young man after 80, named sun Xiaoning, a nearby villager. His main business is not growing corn, but raising cattle. Yes, sun Xiaoning is a famous local cattle farmer. He raised more than 60 cattle at home, worth more than 100 million yuan. It turned out that the man in front of him was a millionaire.

According to sun Xiaoning’s daughter-in-law’s plan, I want to take advantage of the good market and plan to add some calves and expand the breeding scale at the end of the year, so that I will have a lot of income in the coming year. But her husband sun Xiaoning didn’t think so. He loved playing with machinery since childhood, but he was full of interest in agricultural machinery. At the beginning of the year, despite his wife’s opposition, he spent more than 200000 yuan to buy a corn harvester. This new corn harvester can not only harvest corn, but also collect broken corn stalks.

Unlike others who go out to work, sun Weili and his wife started breeding at home. They lived a busy and prosperous life. According to their daughter-in-law’s ideal, they would add some calves at the end of the year, and appropriately expand the breeding scale while taking advantage of the good yellow cattle price, so that they could make more money.

So why did sun Xiaoning buy a corn harvester alone? Because he is a cattle farmer and needs a lot of feed to feed cattle every day, but his corn is not enough at all. He even often has to buy corn from his neighbors. This new corn harvester solves this problem very well. This not only solves the feeding problem, but also saves manual picking up corn stalks.

As mentioned above, there are relatively few such corn harvesters, so nearby villagers come to sun Xiaoning to help harvest the corn field. Because there are many local farmers like sun Xiaoning, almost every family grows more than 10 mu of corn.

Often, everyone will harvest the corn before it is fully mature, because the green feed produced in this way has the highest nutritional value. Some farmers harvest corn in advance in order to plant another crop of fast-growing leafy vegetables, so as to improve economic benefits.

The unique corn harvesting method not only reduces the feeding cost of farmers, but also brings huge business opportunities for sun Xiaoning. However, he can’t be busy with hundreds of acres of corn fields in the village. Even if he works overtime all day, he has to be busy for more than half a month to finish his work. Sun Xiaoning’s daughter-in-law said with a bitter smile: although she can earn 60 yuan per mu by harvesting corn, she is particularly distressed by her husband’s high-intensity work, Even when eating, I often take a few random bites in the cab.

In fact, how many people know who is naturally willing to suffer, but it is just a burden on his shoulders?

-

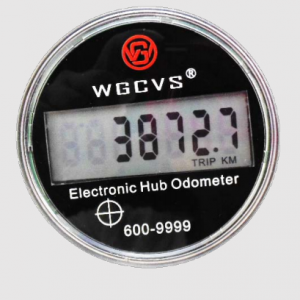

trailer axle hub odometer china factory price

Scheduling maintenance;

Determine lease charges;

Validating guarantees;

Calculating cost per mile.

-

10ton □100mm square beam axle for Agriculture trailer use

Certificate: CE Examination Certificate

Has had a range of Axle Assemblies examined to the Machinery Directive 2006/42/EC, as amended.

UK Examination Certificate

Has had a range of Axle Assemblies examined to the Supply of Machinery (Safety) Regulation 2008 SI 2008/1587, as amended by SI 201/1043, SI 2011/2157 and SI 2019/696.

-

11 ton Ø127mm round beam lowbed axle for lowboy truck trailer

Axle track: 1950mm (Customerized)

Total length: 2234mm

PCD:Ø225

Max. Capacity: 11000(kg)

Axle beam:Ø127*16

Brake specification: Ø311*190

Stud:10-M22x1.5

Recommend wheel fixing: 6.5-15

Bearing installation: HM212049/HM212011

HM218248/HM218210

Slack adjuster: Automatic or Manual (Optional)

-

16ton drum type axle

Durable axle for container semitrailer

China axle production technology become more stable and have good reputation. Every year have 300,000 trucks demand update in domestic market. About 50% are flatbed trailer for carry containers. Fuel tank demand about 10%. Most of trailers are use china made axle. After 20 years road test experience, china trailer axle become more reliable.

From 2020, all dangerous cargo should use disc wheel axle with air suspension. Which can let the transportation more safety and stable.

-

Fuwa American style axle

Axle beam use 20Mn2 seamless pipe, through one-piece press forging and special heat-treatment, which has great over loading capacity and high intensity.

Axle spindle,which was processed by digital controlled lathe, is made of alloy material.

The bearing position is processed by the method of hardending operation,therefore the bearing can be fixed by hand instead of heating, also convenient for maintain and fixing.

Axle spindle is connected by the by submerged arc welding, which make the whole beam more reliable and solid.

Axle bearing position is used the grinding machine to keep the bearing at the same level, after processing, it can assure that the concentricity within 0.02mm strictly.

Axle grease lubricant is supplied by EXXON Mobile which could provide high lubricating performance and protect bearing well.

Axle brake lining is high performance, non-asbestos, non-pollution and long service life.

To make check and replace easily, also come with the position of the exhaustion to remind customer to check and maintain.

Axle bearing is adopted famous brand in China, with the advantages of over loading capability, High rotating speed, good intensity, abrade resistant and heat resistant.

-

Steering axle

How to deal with the problem that the wheels of the truck cannot return to the right position automatically after steering? The main reason why the wheels of a car can automatically return to the right position after steering is that the positioning of the steering wheel plays a decisive role. The kingpin caster and kingpin inclination play a decisive role in the automatic return of the steering wheel. The righting effect of kingpin caster is related to vehicle speed, while the righting effec... -

MBP 14T german type axle

MBP brand 14t axle is one of the best axle manufacturer in china

-

MBP 16t german type axle with slack adjuster

Malfunction reason & Troubleshooting for 16 ton axle

-

16t BPW axle use 200mm width brake shoe assembly for repair

What determines the braking performance? Brake performance generally depends on two important parts: one is the brake valve, the other is the brake pad.

-

Brake shoe repair kit and cam shaft repair kit is helping you in axle maintenance

Maintenance of axle. Note: 1. Maintenance checking should be carried out when the vehicle is free of load. 2. When lift the vehicle, the whole axle should be lifted together, if a jack is used, the supporting position should be close to the leaf spring, and underlay one piece of thick steel plate so as to avoid less stress concentration on part of the Axle.

-

How to lubrication and maintenance for trailer axle

Lubrication and maintenance of axle, please find the details showing in the below table.

Note:1. If the vehicle runs under the bad conditions, the frequency of lubrication and maintenance should be increased.

2. It should be used the NO.2 Lithium base grease with the suitable temperature from -30℃ to 180℃ . MBPAP special grease package or (Retinax) LX2 grease is recommended, it’s used 1.5kgs per axle each time.