Brake shoe repair kit and cam shaft repair kit is helping you in axle maintenance

A.Check the Wheel Nuts are tightened or not.

After the first run of a new vehicle, or after 15 days of each running, or whenever a tire is replaced, use a Torsion Spanner to tighten the nut crisscross diagonally to the Rated Value.

Wheel stud M22 X 2 Tightening torque:430N.m

Wheel stud M22 x 1.5 600N.m

Wheel stud M20 x 2 335N.m

For Trilex wheel stud, tighten the Nuts with Torsion Spanner along the wheel to the Rated Value by several Times.

B.Pulling the slack adjuster manually to check the wheel brake clearance

According to the use condition, adjust it every 10-20 days. By adjusting the hexagon head, adjust the stroke “a” to 10~12% value of “b” which is the length of connecting brake adjuster. For example, if the arm length “b” is 150mm, the value of “a” should be 15-18mm. If pulling the slack adjuster manually, when brake chamber piston stroke “a” reaches the value of 35mm, the wheel brake clearance should be readjusted.

Regulating method: use a Spanner to adjust Hexagon Head clockwise to the Brake position, then anticlockwise turn it back for 3-4 scales (90-120 angle), and spring back the Lock Sleeve so as to lock the Hexagon Head.

C.Check the thickness of the brake lining

Every three months, check the thickness of the brake lining through the peep hole on the dust cover, when the thickness of the brake lining is only 6mm left, or the brake lining were abrased to its edge indicating line, the brake lining must be replace.

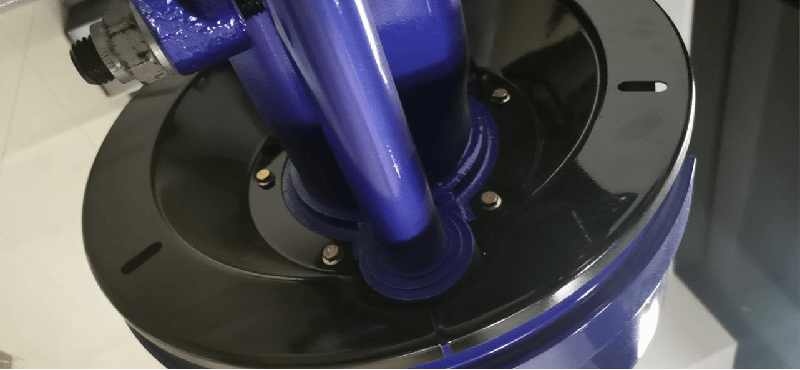

D.Check the working condition of the wheel hub bearing.

Check the working condition of the Wheel Hub Bearing every 6 months. Lifting the Axle until the wheels leave the ground, put 2 sticks between the Wheel and the ground to check the rotating condition of the Shaft. Readjust it if the rotation is abnormal.

Procedure of wheel hub bearing regulating:

1.Release the Hub Cap.

2.Remove the Split pin from the Axle Head.

3.Use the special Octagon Sleeve and Torsion Spanner to tighten the nut to Rated Torque value (150+8/-23 N.m) while rotating the wheel hub.

If there is no suitable torsion spanner, use the hand to turn the wheel hub until the brake is working. And then anticlockwise turn the nut to the pin hole, the most rotatory degree is 30 (namely:1/12 loop).

1.Insert the Split pin and bend the end of the Split pin a little.

2.Put on the Hub Cap and tighten it at torque 800 N.m

E.Check the tightening of the Hub Cap

Check the tightening of the Hub Cap with the special Octagon Sleeve and Torsion Spanner every 6 months.

Check the irregular wearing of the tires every 3 months.

Visually check the damaged and wearing condition of all the components every 6 months.

Replace the bearing if the following condition is occurred:

1.The rotor is worn-out

2.Crack and erosion on the bearing, the support and the rollers.

3.If breaking-off and burn trace found on the bearing and the rollers.

FAQ

Q1. What is your terms of packing?

A: Generally, goods are sealed in ploy bags and packed in cartons and pallet or wood cases.

Q2. What is your terms of payment?

A: T/T (deposit + balance before delivery). We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 25 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample for free charge if we have ready parts in stock, but the customers have to pay the courier cost.

Q7. How do you make our business long-term and good relationship?

A: We provide our clients with one-stop service, from specific component to final assembled products, solving various problem for different clients all over the world.