KNORR 155427N50 Pilot relay valve

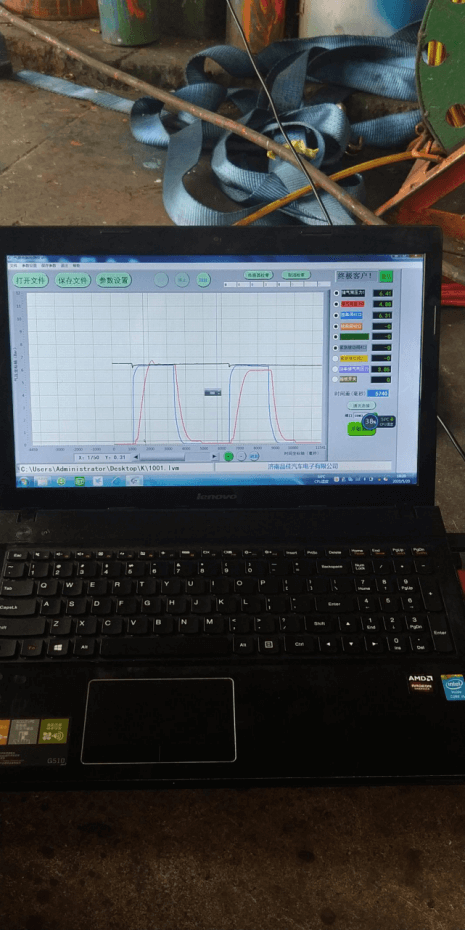

The inlet of the relay valve is connected with the air reservoir, and the outlet is connected to the brake air chamber. When the brake pedal is pressed, the output air pressure of the brake valve is used as the control pressure input of the relay valve. Under the control pressure, the air inlet valve is pushed open, so the compressed air enters the brake air chamber directly through the air inlet through the air reservoir, instead of flowing through the brake valve, which greatly shortens the charging pipeline of the brake air chamber and accelerates the filling process of the air chamber. Therefore, the relay valve is also called the acceleration valve.

The relay valve is used at the end of a long pipeline to make the compressed air in the air reservoir fill the brake chamber quickly, such as in the braking system of a trailer or semi-trailer.

Generally, differential relay valve is used. To prevent the simultaneous operation of the driving and parking systems and the overlapping of the forces in the combined spring brake cylinder and the spring brake chamber, so as to avoid the overload of the mechanical transmission elements and the rapid charging and discharging of the spring brake cylinder.

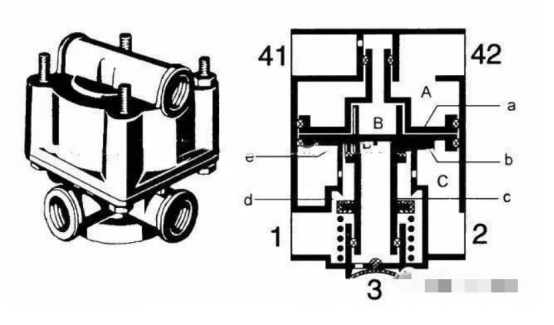

Differential relay valve

1.The purpose is to prevent the overlapping of forces in the combined spring brake cylinder and brake chamber (spring brake chamber) when the service brake and parking brake systems are operated at the same time, so as to avoid the overload of mechanical transmission components and make the spring brake cylinder charge and exhaust quickly. 2. Working principle driving state driving state, the hand brake valve continuously supplies air to chamber a through 42 ports. The piston (a) and the piston (b) are pressed downward, close the exhaust valve (E), push the valve rod (c) downward, open the intake valve (d), and the compressed air from the air reservoir through one port is output through two ports. The spring brake chamber connected with the two ports is provided with compressed air, and the spring brake is released.

When the service brake system operates independently When the main brake is operated, the compressed air enters chamber B through port 41 to press down piston B. due to the reaction force of chamber a and chamber C, the pressure reaching chamber B has no effect on the operation of the differential relay valve. The compressed air continues to flow to the spring brake part of the spring brake chamber to release the brake. At the same time, the compressed air directly from the tractor brake valve makes the diaphragm part work again.

When the parking brake system operates independently, when the hand brake valve is operated, the part of chamber a is completely emptied. The piston (a) is not under pressure, and is pushed upward by the piston (b) exposed to the air pressure of the air reservoir in cavity C. the exhaust valve (E) is opened, and the valve stem (c) rises to close the intake valve (d). In this way, according to the position of the hand brake handle, the spring brake cylinder makes the gas discharge through port 2, valve rod (c) and exhaust valve 3, thus spring braking.

During partial braking, the exhaust valve (E) is closed after exhausting, and the air pressure in cavities A and C is balanced, and the differential relay valve is in the balance position. However, when fully braked, the air inlet (d) continues to open. When the main brake and spring brake act at the same time, a When the spring brake cylinder acts, the compressed air enters chamber B through port 41 and acts on the piston (b). As chamber C is empty, the piston (b) moves downward, closes the exhaust valve (E) through the valve stem (c) and opens the air inlet valve (d). The compressed air from port 1 reaches port 2 through chamber C and enters the spring brake chamber.

The spring brake is released according to the rising degree of service brake pressure, so as to avoid the overlapping effect of the two kinds of brake. B. When the inlet pressure is higher than the pressure in chamber B, the pressure in chamber C pushes the piston (b) up, the inlet valve (d) is closed, and the differential relay valve is in balance

FAQ

Q1. What is your terms of packing?

A: Generally, goods are sealed in ploy bags and packed in cartons and pallet or wood cases.

Q2. What is your terms of payment?

A: T/T (deposit + balance before delivery). We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 25 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample for free charge if we have ready parts in stock, but the customers have to pay the courier cost.

Q7. How do you make our business long-term and good relationship?

A: We provide our clients with one-stop service, from specific component to final assembled products, solving various problem for different clients all over the world.