Structure of diaphragm T30 brake chamber and T3030 air booster

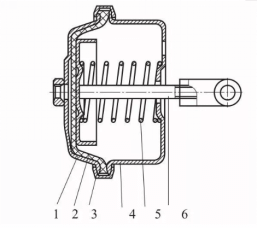

Diaphragm brake chamber

1 - cover; 2 - diaphragm; 3 - clamp;

4 - shell; 5 - return spring; 6 - push rod

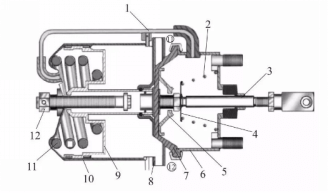

Structure of diaphragm piston combined brake chamber

Taking the diaphragm piston combined brake chamber of EQ1118GA automobile as an example, its structure is explained.

The diaphragm piston combined brake chamber is composed of diaphragm brake chamber and spring brake chamber, and the two parts are relatively independent, as shown in the figure. The diaphragm brake part is used for service brake, and the spring brake part is used for parking brake and emergency brake.

Structure of diaphragm piston combined brake chamber

1 - vent pipe; 2 - return spring; 3 - push rod;

4 - spring seat; 5 - push plate; 6 - end cover;

7 - diaphragm; 8 - diaphragm; 9 - piston; 10 - spring brake chamber;

11 - energy storage spring; 12 - Loosening bolt;

⑪ - service brake air inlet; ⑫ - parking / emergency brake air inlet

When the handle of the manual control valve is in the parking position, the air inlet valve is closed and the exhaust valve is opened, the spring brake air chamber is connected with the atmosphere, and the piston is close to the diaphragm brake air chamber under the action of energy storage spring, and the push rod is pushed out to generate parking brake force.

When the handle of the manual control valve is in the driving position, the exhaust valve is closed and the air inlet valve is opened. Compressed air enters the spring brake air chamber through the manual control valve, pushing the piston away from the diaphragm brake air chamber. The push rod and diaphragm of the diaphragm brake air chamber return to position under the action of return spring to release the parking brake.

But to overcome the spring force, the air pressure of the brake system must reach the specified value, so the air reservoir must be inflated before the car starts. After the parking brake is released, the diaphragm brake air chamber controlled by the valve in the upper chamber of the service brake valve returns to normal operation, namely, the air inflation generates the brake and the exhaust brake is released.

When the service brake system is not working normally, the emergency function of the manual control valve can be used to drive at low speed. The handle of the manual control valve turns from the service position to the parking brake position at different angles (12 ° ~ 73 °), the compressed air of the exhaust part of the spring brake air chamber, and the piston moves to the diaphragm brake air chamber for a certain distance under the action of energy storage spring. At this time, the rear brake produces corresponding braking force. When the handle is released, the spring brake air chamber immediately restores the initial air pressure and completely releases the brake.

When the spring brake chamber cannot build up enough air pressure, but the parking brake needs to be released to move the vehicle, the loosening bolt at the end of the spring brake chamber can be operated. The bolt passes through the center hole of the piston and is installed on the shell of the spring brake chamber through the thread. In the process of screwing out the bolt, the nut will drive the piston away from the diaphragm brake chamber and release the brake. If parking brake force is required, the release bolt must be fully screwed into the spring brake chamber.

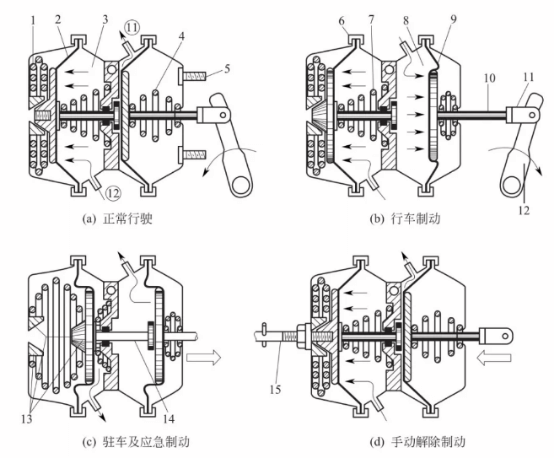

Structure of diaphragm piston combined brake chamber

As shown in Figure 6-30, a kind of diaphragm diaphragm combined brake chamber is composed of parking brake chamber 3 and service brake chamber 8 in series, so it can complete service brake and emergency brake.

The brake chambers 3 and 8 each have a vent port a and B, which are respectively connected with the parking / emergency and service brake pipelines. When the service brake is applied, step on the brake pedal, that is, compressed air is filled into the service brake through the vent B

Figure 6-30 working principle of diaphragm diaphragm combined brake chamber

1 - energy storage spring; 2 - parking brake chamber diaphragm;

3 - parking brake chamber; 4, 7 - return spring;

5 - mounting bolt; 6 - clamp; 8 - service brake chamber;

9 - service brake chamber diaphragm; 10 - brake push rod;

11 - connecting fork; 12 - adjusting arm;

13 - conical head and conical seat; 14 - energy storage spring push rod;

15 - screw; ⑪ - service brake air inlet;

⑫ - parking / emergency brake air inlet

FAQ

Q1. What is your terms of packing?

A: Generally, goods are sealed in ploy bags and packed in cartons and pallet or wood cases.

Q2. What is your terms of payment?

A: T/T (deposit + balance before delivery). We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 25 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample for free charge if we have ready parts in stock, but the customers have to pay the courier cost.

Q7. How do you make our business long-term and good relationship?

A: We provide our clients with one-stop service, from specific component to final assembled products, solving various problem for different clients all over the world.