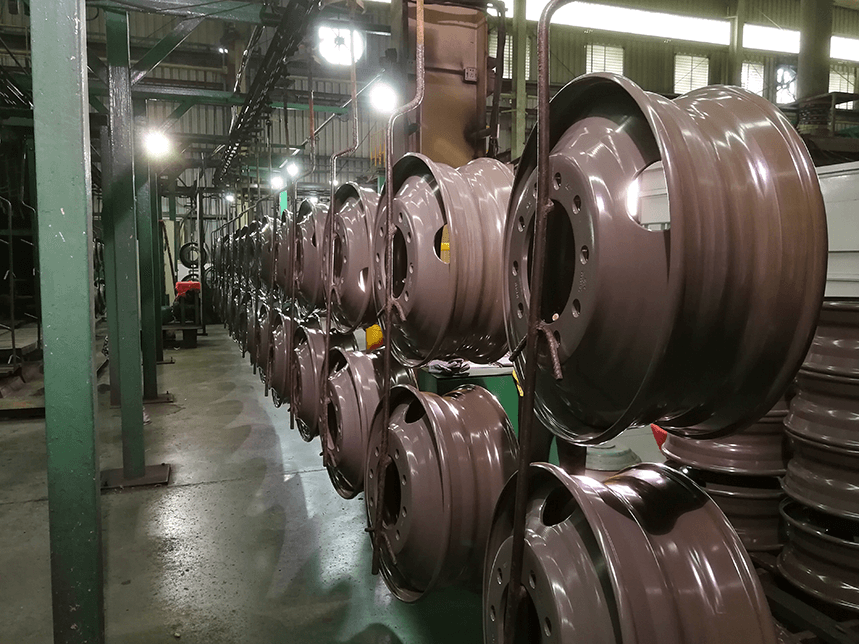

3 PC 8.5-24 Heavy Duty Truck Wheels

1.Particular patent design of big flange, eliminating the hidden danger of bursting the tire.

2.Flange angle changes from vertical to round-radian, decreasing the friction, and lessening the generation of heat.

3.Bigger and thicker flange making your wheel resist more pressure.

4.Patent design of wider rim, relieving the pressure on tire.

5.Spinning technics making longer lifetime of disc than common punching technics.

By microscope, spinning technics making the atom structure of steel undestroyed.

By microscope, pushing technics making the atom structure of steel destroyed and cracks appear.

Advantages of aluminum alloy steel rim:

1. Energy saving, good heat dissipation. The use of aluminum alloy steel rim can reduce the weight of the whole vehicle, reduce the rotation inertia of the wheels, improve the acceleration performance of the vehicle, reduce the demand for braking energy, so as to reduce the fuel consumption.

2. High security. For high-speed vehicles, high temperature tire burst and brake efficiency reduction caused by tire landing friction and braking are common. The heat conduction coefficient of aluminum alloy is three times that of steel and iron, so it is easy to disperse the heat generated by tires and chassis in the air. Even in the case of long-distance high-speed driving or continuous braking on downhill road, it can keep the vehicle at an appropriate temperature and reduce the tire burst rate.

3. High bearing capacity. The bearing energy of aluminum alloy steel rim is five times of that of ordinary iron rim. The forged wheel only deforms 5cm after bearing 71200kg. In other words, the strength of the aluminum alloy rim is five times that of the iron rim.

4. Beautiful appearance. The fluidity and tension of aluminum alloy in high temperature liquid state is better than that of steel rim, and the later polishing and electroplating process can make it more beautiful and changeable appearance; the surface anti-corrosion treatment and electrostatic powder coating also make it as long as new.

Product parameters

|

Wheel size |

Tire size |

Bolt type |

Center hole |

PCD |

Offset |

Disc thickness(convertible) |

Approx. Wt. (kg) |

|

10.00-20 |

14.00R20 |

10,27 |

281 |

335 |

115.5 |

14 |

68 |

|

|

|

|

|

|

|

|

|

|

8.5-24 |

12.00R24 |

10,26 |

281 |

335 |

180 |

14/16 |

69 |

|

8.5-24 |

12.00R24 |

10,27 |

281 |

335 |

180 |

14/16 |

78 |

|

|

|

|

|

|

|

|

|

|

8.5-20 |

12.00R20 |

10,26 |

281 |

335 |

180 |

14/16 |

53 |

|

8.5-20 |

12.00R20 |

10,27 |

281 |

335 |

180 |

14/16 |

61 |

|

8.5-20 |

12.00R20 |

8,32 |

221 |

285 |

180 |

16 |

55 |

|

8.5-20 |

12.00R20 |

10,32 |

222 |

285.75 |

180 |

16 |

55 |

|

|

|

|

|

|

|

|

|

|

8.00-20 |

11.00R20 |

10,26 |

281 |

335 |

175 |

14 |

50 |

|

8.00-20 |

11.00R20 |

10,27 |

281 |

335 |

175 |

14/16 |

53 |

|

8.00-20 |

11.00R20 |

8,32 |

221 |

285 |

175 |

14/16 |

53 |

|

8.00-20 |

11.00R20 |

10,32 |

222 |

285.75 |

175 |

14/16 |

53 |

|

|

|

|

|

|

|

|

|

|

7.50V-20 |

10.00R20 |

10,26 |

281 |

335 |

165 |

13/14 |

47 |

|

7.50V-20 |

10.00R20 |

10,27 |

281 |

335 |

165 |

14/16 |

47 |

|

7.50V-20 |

10.00R20 |

8,32 |

221 |

285 |

165 |

14/16 |

50 |

|

7.50V-20 |

10.00R20 |

8,32 |

214 |

275 |

165 |

14 |

47 |

|

7.50V-20 |

10.00R20 |

10,32 |

222 |

285.75 |

165 |

14/16 |

50 |

|

|

|

|

|

|

|

|

|

|

7.25-20 |

10.00R20 |

8,32 |

221 |

285 |

158 |

13 |

49 |

|

|

|

|

|

|

|

|

|

|

7.00T-20 |

9.00R20 |

8,32 |

221 |

285 |

160 |

13 |

40 |

|

7.00T-20 |

9.00R20 |

8,32 |

214 |

275 |

160 |

13 |

40 |

|

7.00T-20 |

9.00R20 |

10,32 |

222 |

285.75 |

160 |

13/14 |

40 |

|

|

|

|

|

|

|

|

|

|

6.5-20 |

8.25R20 |

6,32 |

164 |

222.25 |

135 |

12 |

39 |

|

6.5-20 |

8.25R20 |

8,32 |

214 |

275 |

135 |

12 |

38 |

|

6.5-20 |

8.25R20 |

8,27 |

221 |

275 |

135 |

12 |

38 |

|

|

|

|

|

|

|

|

|

|

6.5-16 |

8.25R16 |

6,32 |

164 |

222.25 |

135 |

10 |

26 |

|

|

|

|

|

|

|

|

|

|

6.00G-16 |

7.5R16 |

6,32 |

164 |

222.25 |

135 |

10 |

22.5 |

|

6.00G-16 |

7.5R16 |

5,32 |

150 |

208 |

135 |

10 |

23 |

|

|

|

|

|

|

|

|

|

|

5.50F-16 |

6.5-16 |

6,32 |

164 |

222.25 |

115 |

10 |

18 |

|

5.50F-16 |

6.5-16 |

5,32 |

150 |

208 |

115 |

10 |

18 |

|

5.50F-16 |

6.5-16 |

5,29 |

146 |

203.2 |

115 |

10 |

18 |

|

5.50F-16 |

6.5-16 |

5,32 |

133 |

203.2 |

115 |

10 |

18 |

|

5.50F-16 |

6.5-16 |

6,15 |

107 |

139.7 |

0 |

5 |

16 |

|

5.50F-16 |

6.5-16 |

5,17.5 |

107 |

139.7 |

0 |

5 |

16 |

|

|

|

|

|

|

|

|

|

|

5.50-15 |

6.5-15 |

5,29 |

146 |

203.2 |

115 |

8 |

16 |

FAQ

Q1. What is your terms of packing?

A: Generally, goods are sealed in ploy bags and packed in cartons and pallet or wood cases.

Q2. What is your terms of payment?

A: T/T (deposit + balance before delivery). We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 25 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample for free charge if we have ready parts in stock, but the customers have to pay the courier cost.

Q7. How do you make our business long-term and good relationship?

A: We provide our clients with one-stop service, from specific component to final assembled products, solving various problem for different clients all over the world.