wheel hub

What kind of machine tool is more suitable for processing brake drum?

BPW 12T 0327248320 hub oem number 0327262270 and 0327280140

In 2020, the production and sales of commercial vehicles will exceed 5 million for the first time, reaching a record high, with a year-on-year growth of 20.0% and 18.7% respectively. Among them, the number of heavy trucks reached a record high of 1.62 million in china.

China has a vast territory, complex terrain and heavy vehicle load, so the drum brake is bound to become the preferred configuration for more than 90% of medium and heavy truck products. Due to the friction between the downhill and the brake shoe for a long time, the temperature keeps rising. In order to prevent the brake heat decay, spray cold water is often used to cool down. The sharp change of the temperature difference between the cold and hot in a short time and the friction for a long time cause the brake drum to wear quickly, and the market demand is very large.

Today, we mainly discuss the processing of brake drum of chassis shaft end products with large consumption in automobile parts.

Brake drum, as the most representative part of disc drum products, is the friction couple of drum brake. In addition to the strength and rigidity required as a component, it should also have as high and stable friction coefficient as possible, as well as appropriate wear resistance, heat resistance, heat dissipation and heat capacity.

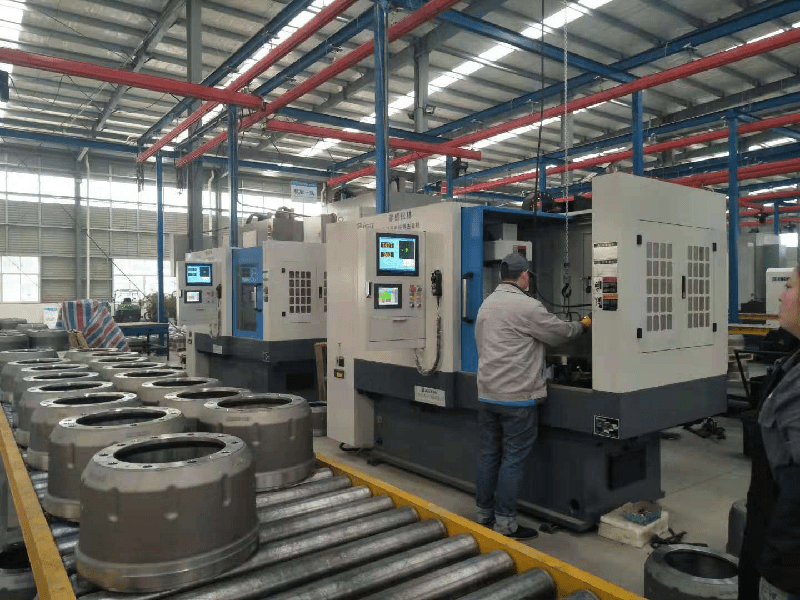

At present, the main material of brake drum is gray iron 250. In addition, a small part of brake drum is made of ductile iron and vermicular iron. The diameter of the product is about 300-500 mm, the height is about 150-300 mm, and the mounting end face has 8-10 bolt holes, which is a typical drum part. For such parts, we choose the combination of CNC vertical lathe lv8508 and CNC vertical plus kf5608 to complete the processing.

The machining allowance of brake drum is generally 2mm-3mm on one side. Due to the need of casting draft angle, the machining position of brake surface is long, and the maximum allowance can reach 6mm-7mm. The weight of parts is large. In order to improve the efficiency, cubic boron nitride or ceramic blade is mostly used for cutting gray iron. The linear speed can reach 700m / min, which belongs to heavy-duty cutting, and has high requirements for the rigidity and stability of equipment.

Lv8508 CNC vertical lathe weighs up to 9.5 tons, stable bed structure, with left and right Twin Star structure selection, can easily cooperate with automatic assembly line. All feed shafts adopt hard rail design, which has good transplanting ability. Especially in heavy cutting, it can offset the vibration transmitted from the feed shaft to meet the high-precision product processing.

Lv8508 binary structure.

The spindle adopts hydraulic roller bearing and angular contact bearing at the same time, which can provide higher processing speed and rigidity.

Chuck has the function of secondary pressure clamping. When the cutting force is large, the higher pressure can be used to improve the clamping force, prevent the parts from falling off and provide strong torque transmission; when finishing, the cutting force is small, which is converted to low pressure, reducing the deformation of parts produced by clamping and ensuring the machining accuracy; and the internal cutting stress produced by rough machining can be released during the high and low pressure conversion. The spindle can be equipped with 24 inch chuck at most to meet the requirements of various specifications. The spindle motor can be widely used:

Note: the calculation basis of motor power and torque is S3 25% / 30 minutes (continuous)

The turret adopts high-performance servo motor and three piece coupling, which can accurately and quickly index; the powerful tool clamping force can minimize the deformation of the blade end caused by load, and the outstanding performance is suitable for heavy cutting, and the indexing time is only 0.23 seconds.

Brake drum products due to large market demand, according to the production program belongs to a large number of products, suitable for the use of automatic assembly line production, can achieve the highest efficiency and stable product quality.

Automation puts forward higher requirements for the stability of the equipment, and the following numerical control vertical machining center kf5608 is a product that can operate stably, efficiently and for a long time.

Kf5608 adopts direct spindle, which greatly reduces the acceleration and deceleration time of the spindle.

Using excellent high rigid roller guide with precision servo motor drive can achieve high motion accuracy and stability. The precision preloaded ball screw minimizes the deformation caused by thermal deformation, and the double fixed support mode improves the rigidity. Moreover, the ball screw of each axis and the stable servo motor are connected by metal plate coupling to reduce coupling damage and clearance. The three-axis fast moving speed can reach 36m / min, which reduces a lot of non cutting time.

The machine tools designed and manufactured are based on rich experience in auto parts production, and they can understand the production characteristics of automobile parts and what kind of machine tools can make good parts.

FAQ

Q1. What is your terms of packing?

A: Generally, goods are sealed in ploy bags and packed in cartons and pallet or wood cases.

Q2. What is your terms of payment?

A: T/T (deposit + balance before delivery). We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 25 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample for free charge if we have ready parts in stock, but the customers have to pay the courier cost.

Q7. How do you make our business long-term and good relationship?

A: We provide our clients with one-stop service, from specific component to final assembled products, solving various problem for different clients all over the world.