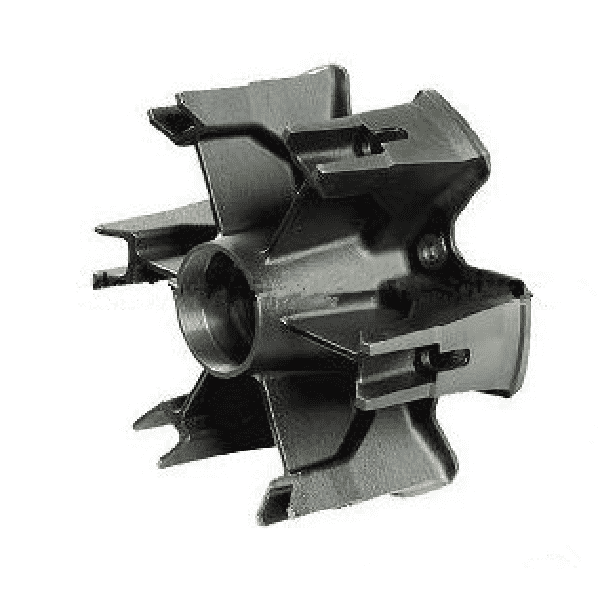

spoke wheel spider

Failure analysis of brake drum

The axle brake drum is an important part of the axle, and it is also the primary inspection part in the daily maintenance of the automobile. According to the feedback information of the company's three guarantee parts, the failure of the brake drum mainly has five situations: cracking, cracking, bottom falling, excessive wear and abnormal wear.

The failure of brake drum is mainly considered from two aspects: one is the material composition and its own strength; the other is the change of mechanical properties caused by the change of material structure under certain working conditions. Generally speaking, its mechanical properties mainly depend on the chemical composition, but also affected by the external environment (temperature, cooling rate, etc.).

Analysis of cracking

The brake drum is mainly subjected to two forces in two directions, one is normal pressure from hoof iron, the other is the tangential force caused by rotation and clutch plate of hoof iron. A lot of heat is generated by friction between brake drum and brake pad, which leads to the increase of temperature of brake drum. In fact, the friction between brake pad and brake drum is spot contact. The heat generated by friction on the contact surface makes the structure change and reduces the thermal fatigue resistance of the place. Due to the uneven heating, the mechanical performance is uneven, and under the frequent braking load, there is a one The crack is discontinuous or continuous under the tangential force, which reduces the thermal fatigue strength of the material. The cracks develop with the continuous crack, and the cracks cross connect to form a network. It is generally said that the cracks cause cracks and serious cracks.

On the other hand, the highest temperature of brake drum can reach 850 ℃ ~ 900 ℃. Eutectic carbide decomposes into graphite and ferrite near 800 ℃ or slightly below 800 ℃; pearlite and ferrite transform into austenite above 800 ℃; austenite transforms into martensite during rapid cooling.

Brake drum cracking

The problem of brake drum cracking should be analyzed from two aspects: one is that the material is cracked due to its own strength difference under the braking state; the other is that the brake drum is cracked under the interaction of thermal stress and phase change stress under the frequent action of external braking force due to the local strength reduction caused by phase change of microstructure under the interaction of thermal stress and phase change stress. With the frequent brake work, the crack gradually extends from the local stress point, and finally passes through the reinforcement belt, resulting in the complete cracking of the brake drum.

Fall to the bottom

There are two aspects of bottom dropping: one is the poor strength of brake drum material; the other is the brake drum cracking caused by unreasonable abnormal external force.

Failure due to excessive wear

The failure of excessive wear mainly refers to the brake drum working belt under the action of frequent braking force, resulting in the brake drum working belt inner diameter geometric size becomes larger, the wall thickness edge is thin, affecting the braking effect, and even brake failure. With the continuous development of new wear-resistant materials, the hardness of the friction plate is also higher and higher, and the requirements for the brake drum (especially the hardness requirements) are correspondingly higher and higher.

Abnormal wear failure

The failure of abnormal wear mainly refers to the groove on the working surface of the brake drum under the action of the hard material of the shoe. This phenomenon is mostly caused by the unreasonable riveting of the shoe friction plate, which also has a certain relationship with the hardness of the brake drum.

FAQ

Q1. What is your terms of packing?

A: Generally, goods are sealed in ploy bags and packed in cartons and pallet or wood cases.

Q2. What is your terms of payment?

A: T/T (deposit + balance before delivery). We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 25 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample for free charge if we have ready parts in stock, but the customers have to pay the courier cost.

Q7. How do you make our business long-term and good relationship?

A: We provide our clients with one-stop service, from specific component to final assembled products, solving various problem for different clients all over the world.